Paraffin, Petrol and Methanol when mixed at the correct fuel to air ratio all provide approximately the same potential Energy (48 ft.lb. per cub inch at NTP). This simplifies calculation to some extent, the main difference is in the quantity of fuel consumed.

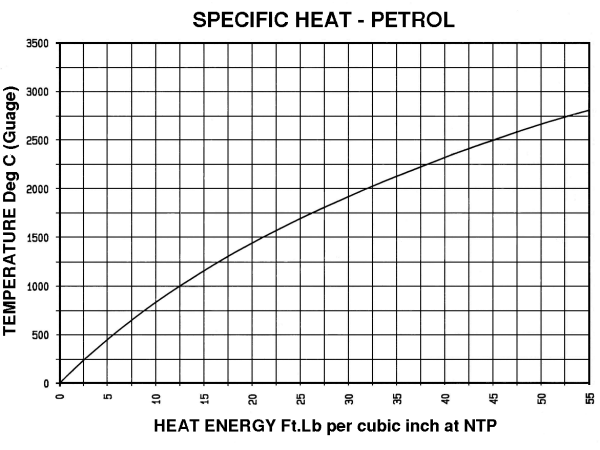

The BSC (Brake Specific Consumption) and BTE (Brake Thermal Efficiency) are calculated using data held in the fuels file. Only one specific heat curve, as below, is applied, this is satisfactory for most purposes. All of the applicable fuels provide similar heat energy when mixed at the correct fuel to air ratio (see Fuel Energy & Air/Fuel Ratio table). Hence BSC and BTE indicated are directly related to this. Whilst the User could change the air to fuel ratio to simulate different strength mixtures, it may not be representative of actual conditions. This is further complicated by the change in burn speed at different mixture strengths. Users should note that the Fuel Energy for all fuels in the current data file is similar. The curve and data on fuels for the greater part has been obtained from Sir Harry Ricardo's books on Internal Combustion Engines.

The latent heat of evaporation of Methanol lowers the induction and scavenge temperature permitting higher compression ratios prior to reaching the melt down limit or pre-ignition occurring. Currently the program uses Petrol as the default because we have suitable data to verify this. Users should note that when Methanol is specified at the same compression ratio a small power increase will occur due to the latent heat of the fuel (change the fuel and observe, the full benefit occurs when the compression ratio is increased).

The potential output of a fuel is limited by the compression ratio, which can be applied without detonation. Subject to this the maximum power output obtainable from any fuel depends on the internal energy of the applied fluid and the latent heat of evaporation.

Some car owners may have experienced carburettor icing; this can be attributed to fuel vaporisation. This is normally due to the latent heat of the fuel. During the vaporisation process a drop in temperature occurs in the inlet tract. This improves scavenge efficiency. Although both Petrol and Methanol have similar energy factors; Methanol will produce greater BHP at the same compression ratio. Paraffin will also produce more power than Petrol at the same compression ratio. However Petrol would detonate at the ratio most suitable to Paraffin. There are examples of multiple fuel engines hence it is important that comparisons are made at realistic compression ratios for the specified fuel (certain military types are so specified.). The brake thermal efficiency and brake specific consumption need to be assessed at the Ideal compression ratio for the comparison to be of real value. Hence if you change the fuel, check that the applied compression ratio is correct.

As already indicated the fuel energy varies very little, however the latent heat does. Generally speaking as regards the true hydrocarbons, the variations in internal energy and latent heat just about balance, with the result that the maximum power output is similar for all. For example, the total internal energy of Benzene is about 1.5% less than that of Hexane, on the other hand the latent heat of Benzene is considerably greater. Hence a greater weight of mixture is retained in the cylinder, with the result that under identical conditions both give the same output within less than 1%.

In the case of alcohol, although the internal energy of the mixture is lower the latent heat is so much greater that a greater density charge occurs in the cylinder. This increase in Volumetric Efficiency produces a power output some 5% greater despite the lower internal energy of alcohol.

The speed of combustion of fuels within an enclosed cylinder varies dependant on residuals and turbulence. This is of greater significance than the free combustion burn speed. It should be noted that highest outputs are obtained with a rich mixture. The added power due to the rich mixture is greater with Alcohol fuels principally due to the latent heat. Engines using Alcohol fuels should not apply lean mixtures.

The program does not yet incorporate facilities for varying the proportion of lubricant in fuel mixtures, the only method currently of investigating the affects of oils and lubricants is to alter the applied friction coefficients within the Test Settings file.

In view of the fact that many model size engines use fuel mixtures containing Nitromethane, the following graph should enable users to appreciate why lower compression ratios are applied in comparison to straight Methanol. Nitromethane is not currently included in the Fuels database, the reason being that energy and specific heat data etc has not yet been established (no documented data has so far been available).

Replacing a percentage of the base fuel with Nitromethane improves combustion raising IMEP at the expense of higher overall fuel consumption. Lower Air to Fuel ratios are required, this eases establishment of the required mixture strength. Synthetic Oils may be required in Two Strokes when the Nitromethane percentage exceeds 40% (normally Castor based lubricants are applied with Methanol).